Enhanced Safety for Passenger Ships thanks to new Fire Safety Solution for Cables

To prevent fires from spreading along cables because of the highly dangerous “gas entrainment” effect, the manufacturer from the South-West of Germany has developed a special compound that is extruded into the cable by way of a highly sophisticated pressure and extrusion process. Thanks to this, combustible gases can no longer migrate through the inside of cables. HB44® C offshore control and signal cables by Hradil are RINA-certified (Registro Italiano Navale) for passenger ships and meet the requirements of IEC 60079-14 and IEC 60331-21 for explosion-hazard areas, placing them in the category of the safest cables in the world. The RINA-certified offshore control and signal cable HB44® C by HRADIL Special Cable comes in 20 different configurations, bespoke solutions are also available on request.

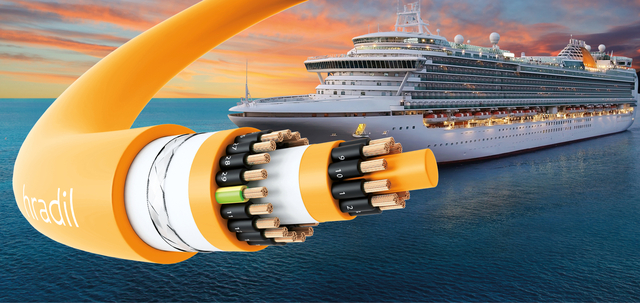

Fig. 1: HB44® C cables by Hradil rank among the safest cables in the world in terms of fire and explosion safety.

Fire propagation caused by “pumping action” of cable

Time and again we hear in the news of fires that have spread to other rooms or areas which, in some cases, were quite fare away from the point of origin, and that cables were to blame for this. The cause for this is almost always what has been described as the “zone entrainment of gases” by pumping action. In other words: the cable pumps the fire into adjoining zones and spaces. What is actually happening is not that the cable as such is on fire and that the flames are propagated along the length of it, which could easily be prevented today by bulkheads. Instead, there is a risk that, fires may actually spread along the insides of cables, invisible to the outside.

The reason for this highly dangerous phenomenon which is caused by a pumping action within the cable is that, because of the way the different cable components are configured, cable insides are never completely compact. Voids form between the cores and fillers which may become filled with combustible gases. Under certain circumstances these may then spread into other areas of the cable. Due this capillary effect, the entrainment of combustible gases into other zones cannot be completely excluded.

Even cables that have been explicitly designed for fire safety normally cannot prevent zone entrainment. While, in the event of a fire, the insulation of many fire safety cables remains largely intact - thanks to the use of mica tape (Muscovite or Phlogopite mica) an insulation material which gives a high degree of protection against high temperatures - it cannot completely stop zone entrainment as described. The risk of negative consequences of the pumping action increases in cables with porous fillers such as non-woven or fibrous materials which are hygroscopic.

Fig. 2: HRADIL RINA-certified offshore control cable HB44® (30x1.5mm2) for explosion-hazard areas acc. to IEC 60079-149-14.

New Fire Safety Solution

The HRADIL Offshore Control and Signal Cable HB44®

IEC 60079-14: 2014 Annex E.1 explicitly calls for cables that are gas tight. Nevertheless, only very few cables fully meet this demand, as the pumping action that may occur inside of cables and which is caused by combustible gases creeping along the inside of cables, cannot be completely prevented. The test in IEC 60079-14:2014 requires cables to have “restricted breathing” , a requirement that, if at all can only be fulfilled in part, for the reasons already described.

Fig. 3: HRADIL RINA-certified offshore control cable HB44® for explosion-hazard areas acc. to IEC 60079-14 cross-section.

Now, this is different in the case of the HB44® C offshore control and signal cable by Hradil. To prevent the dangerous risk of “zone entrainment”, or, in other words, the migration of fires along the cable, Hradil have developed a flame-resistant, halogen free and non-hygroscopic special compound that is pressed into the cable by means of a sophisticated pressure extrusion process. All cores and shielding are potted 100% to ensure that all capillaries and voids are filled up completely with the compound.

The offshore control and signal cables HB44® by Hradil therefore not only meet existing requirements relating to cables used in explosion-hazard areas in terms of mechanical, chemical and thermal loads, but also in terms of zone entrainment. This means that HRADIL’s HB44® offshore control cables fully comply with IEC 60079-14. Users of the HRADIL cable can thus provide full proof of compliance with IEC 60079-14.

The following 20 design variants of the offshore control and signal cables HB44® are available from HRADIL Special Cable, all are RINA-certified according to ELE019618XG:

- HRADIL HB44® C HRADIL-Type No. 150/250V 3x0.75 mm2

- HRADIL HB44® C HRADIL-Type No. 150/250V 28x0.75 mm2

- HRADIL HB44® C HRADIL-Type No. 0.6V/1KV 2x1.5 mm2

- HRADIL HB44® C HRADIL-Type No. 0.6V/1KV 3x1.5 mm2

- HRADIL HB44® C HRADIL-Type No. 0.6V/1KV 3G1.5 mm2

- HRADIL HB44® C HRADIL-Type No. 0.6V/1KV 3G2.5 mm2

- HRADIL HB44® C HRADIL-Type No. 0.6V/1KV 5G1.5 mm2

- HRADIL HB44® C HRADIL-Type No. 0.6V/1KV 5G2.5 mm2

- HRADIL HB44® C HRADIL-Type No. 0.6V/1KV 7G1.5 mm2

- HRADIL HB44® C HRADIL-Type No. 0.6V/1KV 13G1.5 mm2

- HRADIL HB44® C HRADIL-Type No. 0.6V/1KV 18G1.5 mm2

- HRADIL HB44® C HRADIL-Type Nr. 0.6V/1KV 30G1.5 mm2

- HRADIL HB44® C HRADIL-Type No. 0.6V/1KV 36G1.5 mm2

- HRADIL HB44® C HRADIL-Type No. 0.6V/1KV 16G2.5 mm2

- HRADIL HB44® C HRADIL-Type No. 150/250V 2x2x0.75 mm2

- HRADIL HB44® C HRADIL-Type No. 0.6V/1KV 2x2x1.5 mm2

- HRADIL HB44® C HRADIL-Type No. 0.6V/1KV 3x6 mm2

- HRADIL HB44® C HRADIL-Type No. 0.6V/1KV 3x35 mm2

- HRADIL HB44® C HRADIL-Type No. 0.6V/1KV 4x6 mm2

- HRADIL HB44® C HRADIL-Type No. 0.6V/1KV 4x6 mm2

In addition to the approvals acc. to RINA, all HRADIL HB44® cables also fulfil a range of key IEC requirements:

- IEC 60092-350: Electrical installations in ships

- IEC 60092-351: Electrical installations in ships - Part 351: Insulating materials for shipboard and offshore units, power, control, instrumentation, telecommunication and data cables

- IEC 60092-359: Electrical installations in ships - Part 359: Sheathing materials for shipboard high-power and telecommunication cables

- IEC 60092-360: Electrical installations in ships - Part 360: Insulating and Sheathing materials for shipboard and offshore units, power, control, instrumentation and telecommunication cables

- IEC 60092-376: Electrical installations in ships - Part 376: Cables for control and instrumentation circuits 150/250 V (300 V)

- DIN EN 60754-2 VDE 0482-754-2:2015-08 | Test on gases evolved during the combustion of materials from cables and insulated lines | Part 2: Determination of acidity (by pH-measurement) and conductivity

- DIN EN 61034-1 VDE 0482-1034-1:2014-09 | Measurement of smoke density of cables burning under defined conditions

- DIN IEC 60331-21 VDE 0482-331-21:2017-06 Tests for electric cables under fire conditions – circuit integrity.

About Rina

Registro Italiano Navale (RINA) is a ship classification society based in Genova, Italy. Rina’s primary role is the technical monitoring and classification of ships. Around the worlds 3,700 employees work for in Italy and in 64 other countries.