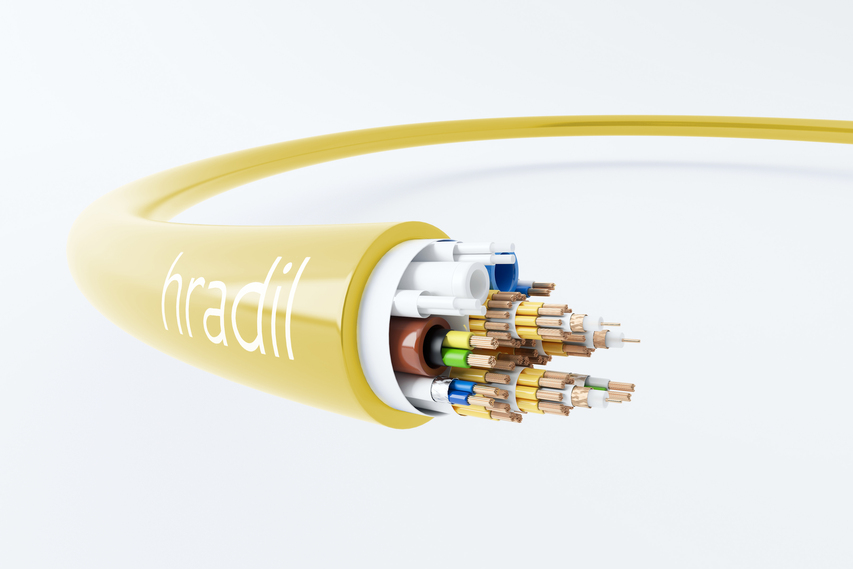

HRADIL High-Performance Hybrid Cable for the Mining and Tunneling Industries

(05 March 2025) Special cable engineers HRADIL are introducing a new hybrid cable at the BAUMA Fair 2025 that has been specifically designed for demanding mining and tunneling tasks. Among others it can be used on tunnel-boring as well as heavy-duty construction equipment. It is also a true multi-tasker enabling power supply, and the simultaneous transmission of data via Cat7 ethernet, fibre-optic cable and CAN bus. Additionally, it features integrated pneumatic and hydraulic hoses.

Fig. 1: HRADIL High-Performance Hybrid Cable for the Mining and Tunneling Industry (AI-generated background)

The Future of Mining and Tunneling: Automation and AI are Key Technologies

Automation, artificial intelligence (AI) and smart data management systems are making increasing inroads into the field of tunnel-boring machinery. At the same time, sensors and hydraulic equipment requirements have become considerably more challenging.

Systems today are typically semi- or fully automated and carry thousands of sensors to monitor processes in real time as well as actuators to control them. With data being recorded for every second and projects lasting several years, thousands of billions of data points are generated and processed by powerful data management systems.

For this reason, cables must meet the most stringent requirements in terms of reliable data transmission. The High-Performance Hybrid Cable is one option provided by HRADIL among others and was specially designed to meet the extreme demands of tunneling and mining tasks. With 40 years of expertise under their belt, HRADIL’s engineers devise solutions that work without fail notwithstanding the toughest conditions, whether mechanical, thermal or chemical.

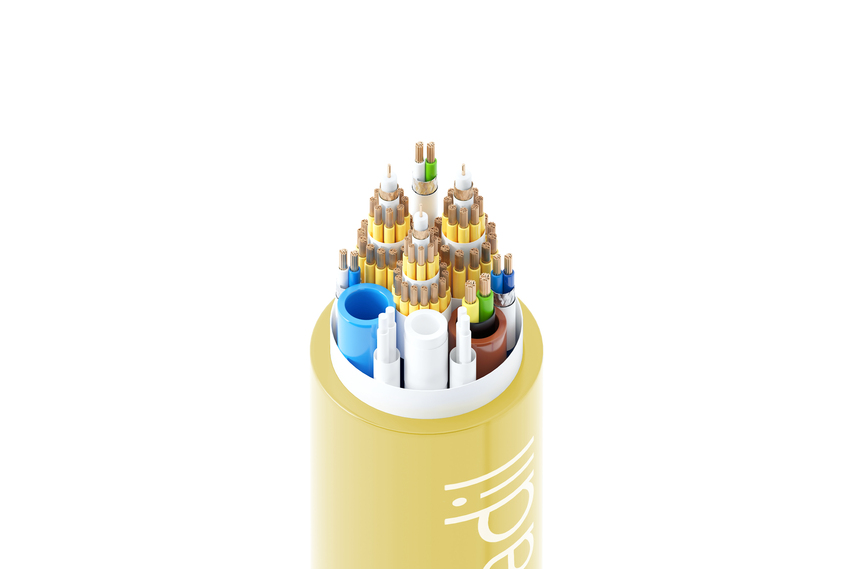

HRADIL High-Performance Cable: A Versatile Hybrid Solution Designed for Maximum Loads in Mining and Tunneling

Fig. 2a: HRADIL High-Performance Hybrid Cable for Mining and Tunneling. Longitudinal view

Fig. 2b: HRADIL High-Performance Hybrid Cable for Mining and Tunneling. Cross-Section

Its innovative design and high-quality materials provide extraordinary mechanical performance characteristics. Thanks to a tensile strength of up to 10,000 N it is capable of withstanding extremely high loads, offering supreme reliability even in the harshest of conditions. Additionally, it can resist extreme temperatures ranging from -40 °C up to +125 °C. It is this versatility because of which cable can be used in a wide range of different environments and applications.

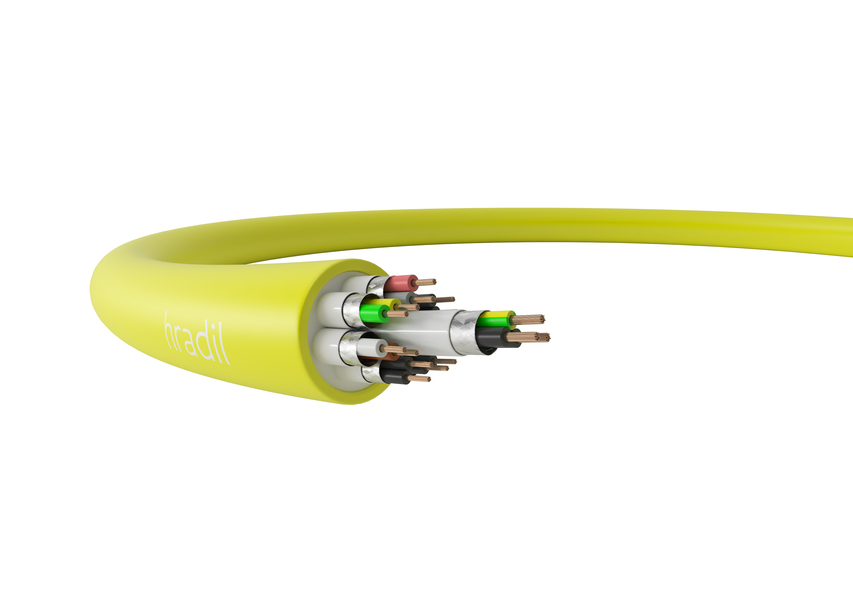

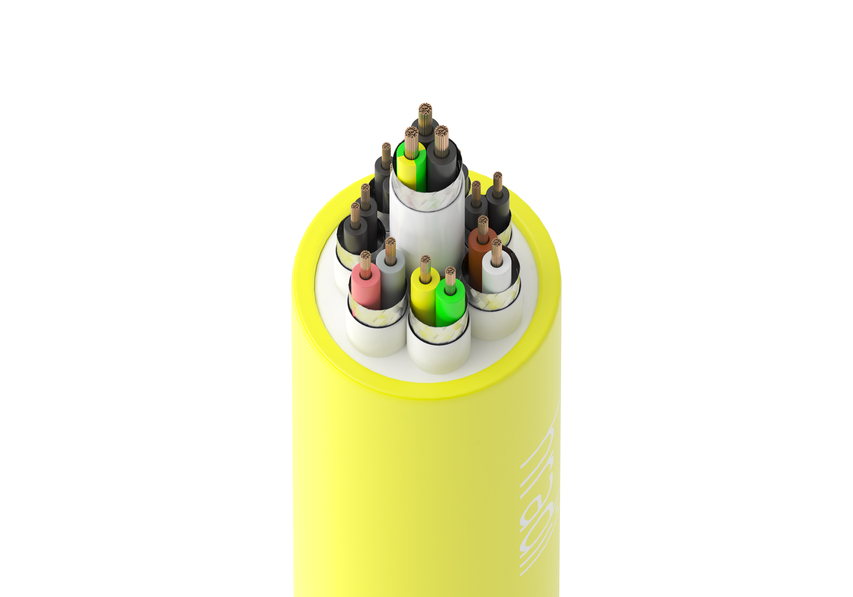

Fig. 3a: Explosion-protected HRADIL Cable for Mining and Tunneling Applications – specially designed for engine power supply and control in demanding environments. Longitudinal view.

Fig. 3b: Explosion-protected HRADIL Cable for Mining and Tunneling Applications – specially designed for engine power supply and control in demanding environments. Cross-section.